Patch’n Plug

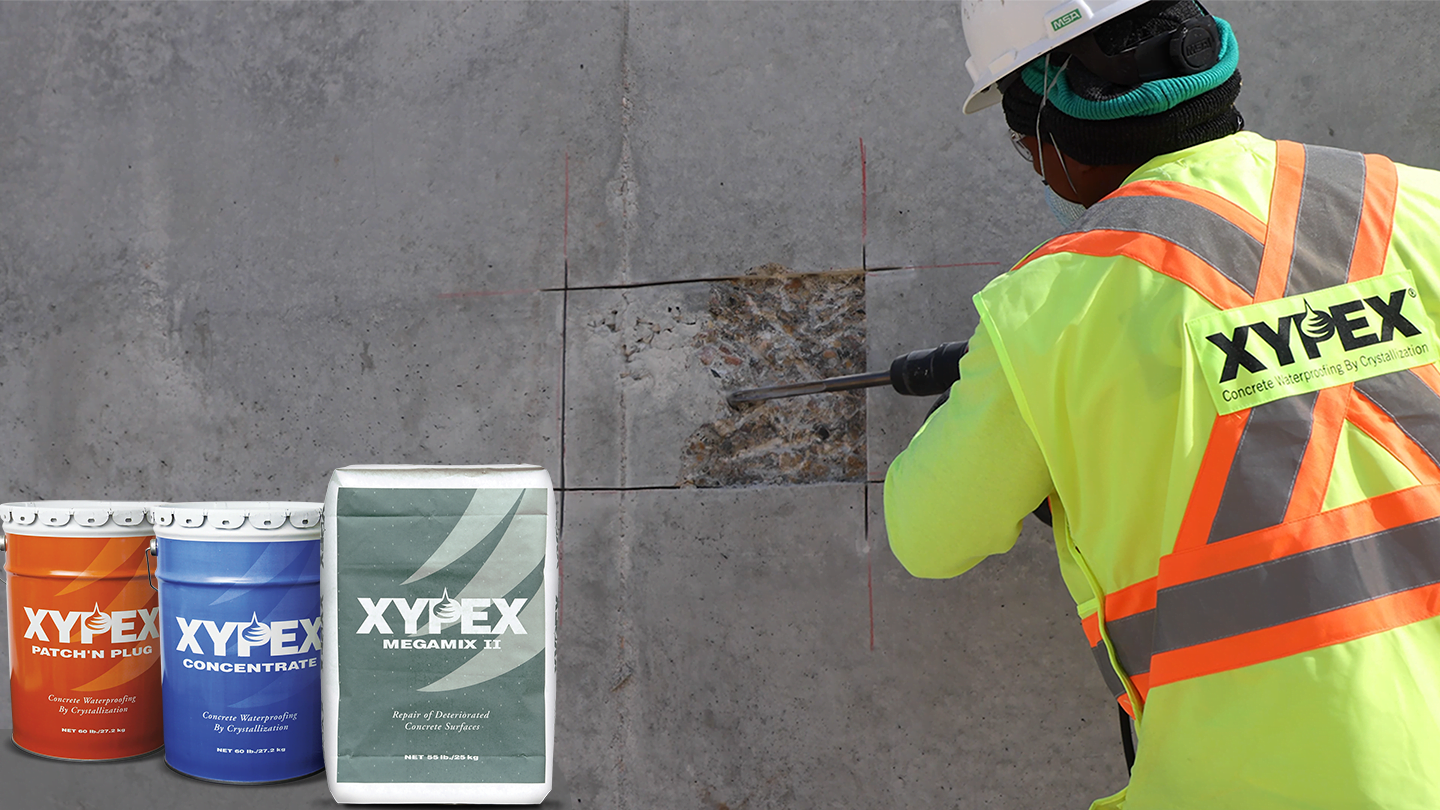

Xypex Patch’n Plug is a specially designed, fast-setting hydraulic cement compound for concrete patching and repair. It stops flowing water in seconds and is used to seal cracks, tie holes, and other defects in concrete. The high performance characteristics of Patch’n Plug are enhanced by Xypex’s unique Crystalline Waterproofing Technology.

Advantages of Xypex

- Single component (simply add water)

- Very rapid setting

- Contains Xypex’s unique crystalline chemistry

for self-healing of cracks and other defects - Quick return to service of water holding structures

- Cement based – compatible with concrete and

masonry substrates - Non-toxic

- No VOCs

- NSF 61 certified

Recommended for

- Stopping an active flow of water through cracks

- Repair of concrete substrates before the application of Xypex coating materials

- Repair of leaking construction joints

- Sealing around pipe penetrations

Packaging

Available in 20 lb. (9.1 kg) pails and 60 lb. (27.2 kg) pails.

Coverage

One 60 lb. (27.2 kg) pail of Xypex Patch’n Plug will produce 0.54 cubic feet (0.0154 cu. metres) of mortar.

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is one year when stored under proper conditions.

Patch'n Plug Application Details

Please refer to the Plugging & Patching Instructions section of the Product Data

Xypex recommended procedures for repairing slabs, walls and other flat concrete surfaces that have dry or leaking cracks and cold/construction joints.

Xypex recommended procedures for repairing wall to slab interface joints and other 90 degree concrete joints; including dry or leaking joints.

Xypex recommended blends of Concentrate and Patch’n Plug to create a longer pot life workable repair mortar that can replace Xypex Concentrate Dry-Pac for many Xypex repair scenarios and procedures.

Xypex recommended procedures and general directions for repairing standard, small to large sized spalls, honeycombs, and other deficiencies.

Xypex recommended procedures for repairing water leaks between conduit, pipe and other utility features (including steel, iron, PVC and HDPE piping) and the concrete elements they pass through.

Xypex recommended procedures for repairing leaking form-ties based on the typical “Plastic Cone Snap Tie” forming tie system (can be modified for other styles of form-ties).

Xypex recommended Estimating Table is a guide only. Actual usage may vary according to the project.

General Resources

Las Esclusas Wastewater Treatment Plant (PTAR)

The Las Esclusas Wastewater Treatment Plant (Las Esclusas PTAR) in the southern area of Guayaquil, Ecuador, is part of the "Project for the Universalization of Sanitary Sewerage." It was designed to improve the region's wastewater management, serving over 1 million residents. This facility, completed on October 7, 2022, reflects a shift toward more effective and sustainable construction methodologies.

Egbin Power Station

In 2018, the Egbin Power Station in Lagos, Nigeria, undertook a significant construction project involving the stabilization of foundations and the construction of a fence. The project spanned 15 months and was marked by a critical design change midway, requiring the piles to be fabricated on land and then submerged in water. Xypex products were chosen for their proven reliability and ability to meet the project's demanding requirements.

Eko Atlantic Water Tank

In 2023, the Eko Atlantic project in Lagos, Nigeria, focused on the waterproofing of a concrete water tank, with Lymex Ltd as the contractor. The project aimed to enhance environmental protection, reduce material costs, and extend the service life of the water tank. Utilizing Xypex Concentrate and Xypex Patch'n Plug, the project achieved significant improvements in waterproofing, sustainability, and longevity.

Yodobashi Umeda Tower

The Yodobashi Umeda Tower project in Osaka, Japan, is a significant investment in retail, entertainment, and urban development. It aims to create an engaging destination while boosting the economic and cultural vitality of Osaka's Umeda district. The tower stands 149.9 meters tall with 35 above-ground stories, housing commercial facilities on the lower levels and the Hanshin-Hankyu Hotel above. Additionally, it features four levels of underground parking.

Flensburg Navy Barrack Conversion

In the picturesque northernmost city of Flensburg, Germany an ambitious project was undertaken to transform a section of an old German navy base into a new focal point for tourism, leveraging its stunning views of the Baltic Sea harbor and the quaint old town center.

Projects Using This Product

The Rihand Dam

Being one of the oldest dams in India, the concrete of the dam body has experienced deterioration due to ageing and AAR (Alkali Aggregate Reaction) resulting in cracking and surface loss. Xypex’s unique crystalline technology was chosen as the preferred repair solution due to its cementitious nature and compatibility with concrete along with other technical reasons.

Sydney Harbour Tunnel

Commencing in September of 1991, repair systems using Xypex Concentrate and Patch’n Plug were used as part of an ongoing program of repair and maintenance of the North and South land driven tunnels and transition tunnels of this renown structure.

AASS Wastewater Treatment Plant

The walls of this plant were cast using the Machihembrado method. Because of this approach, Xypex Dry-Pac and Xypex Patch’n Plug were required to seal the construction joints. The same Xypex treatment was used on 518 m of cold joints and cracks. After these structural defects were repaired, the surfaces were treated with a two-coat application of Xypex Concentrate.

Canóvanas Filtration Plant

The thickening tank (92 ft. diameter by 15 ft. deep) of this filtration plant used Xypex Patch’n Plug to repair structural defects followed by a coating of Xypex Concentrate. Upon review, the Xypex treatment proved to be very successful, rendering the tank impenetrable by water.

Chehe River Mine

Xypex products were chosen to rehabilitate these pipes as they resist hydrostatic pressure, chemical attack and are a permanent solution thus avoiding future maintenance intervals and shutdowns. Additionally, they are used on wet concrete so removing the need to dry out the concrete before application. Xypex Patch’n Plug was used to seal active leaks in the pipe joints.

Fiat India Automobiles Private Ltd.

More than 13,000 lbs of Xypex Concentrate and 1,000 lbs of Xypex Patch’n Plug were used to waterproof a surface area of 60,000 sq.ft. Xypex was chosen for its additional benefit of chemical resistance and concrete durability enhancement.

Wastewater Tunnel Repair

The first phase of the project required the Bawax applicator to fill in all of the joints between the precast culvert sections with Xypex Patch’n Plug fast-setting hydraulic cement compound. Patch’n Plug stops flowing water in seconds and is used to seal cracks and other holes or defects.